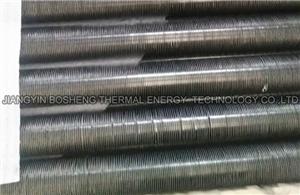

fin tube

-

ASTM A179 Laser Welded Fin Tube With CS Fin For Steam Boiler

Laser welded fin tube 100% welding between fin and base tube without using any filler material, The laser welding process is carried out under the protective atmosphere, and no impurity of the weld seam. The Laser Welded Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

Email Details -

Hot

SA334 GR6 Heat Exchanger Low Fin Tube

Low fin tube Low fin tube are mainly used in the condnsers and evaporators for air cooler and refrigerator, absorption refrigerator, oil cooler and other heat exchangers. And other industry such as coal power stations, nuclear power stations,boat heat exchangers, air cooler. Heat recovery system, dryers and heaters in chemical industries.

Email Details -

SA213 TP316 Low Fin Tube

Low fin tubes are mainly used in the condnsers and evaporators for air cooler and refrigerator, absorption refrigerator, oil cooler and other heat exchangers. And other industry such as coal power stations, nuclear power stations,boat heat exchangers, air cooler. Heat recovery system, dryers and heaters in chemical industries. .

Email Details -

SA213 TP304 /AL1060 Knurled KL Fin Tube For Heat Exchanger Parts

KL Fin (or Knurled L fin): with metal strip wounded on the core tube with knurled suface The fin is wrapped around the tube and the foot is rolled into the outer surfaceof the pre knurled tube and secured at each end. Gives good surface protectionto the tube and improved heat transfer compared to the L or LL type fin. Usedfor moderate temperature cool applications.

Email Details -

SS316 Tension Wound KLM Overlapped Type Aluminum Fin Cooling Tube

KL Fin (or Knurled L fin): with metal strip wounded on the core tube with knurled suface The fin is wrapped around the tube and the foot is rolled into the outer surfaceof the pre knurled tube and secured at each end. Gives good surface protectionto the tube and improved heat transfer compared to the L or LL type fin. Usedfor moderate temperature cool applications.

Email Details -

SA334 Gr6 Knurled(KL) Aluminum Fin Cooling Tube

KL Fin (or Knurled L fin): with metal strip wounded on the core tube with knurled suface The fin is wrapped around the tube and the foot is rolled into the outer surfaceof the pre knurled tube and secured at each end. Gives good surface protectionto the tube and improved heat transfer compared to the L or LL type fin. Usedfor moderate temperature cool applications.

Email Details -

SA213-TP304 AL1060 Overlapped LL Foot Soldered Fin Tube

LL-type finned tube makes the trapezoidal cross-section forming by rolling combine closely with the heat flux density distribution size. The fins combine tightly with the tube,which makes the thermal efficiency higher and put an end to thermal resistance that brings by the non eliminate contact from segment gap of the string type finned tube. 1 Features: The winding technology improves production efficiency and heat transfer, makes the average fin pitch and higher proportion between fins and tube. At the same time, the base tube can be protected from air erosion. 2 Application: LL-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system. The fin is wrapped around the tube with an overlapping foot and secured at each end. Gives good surface protection to the tube. Used for moderate temperature coolingapplications. Material: Copper, Carbon Steel, Copper Stainless Steel, Alloy, Aluminium Bare tube OD: 15.88-45mm Fin Pitch: 2.1-5.0mm Fin Height: <16mm

Email Details -

Overlapped Type LL Cooling Aluminum Fin Tube SA179

LL-type finned tube makes the trapezoidal cross-section forming by rolling combine closely with the heat flux density distribution size. The fins combine tightly with the tube,which makes the thermal efficiency higher and put an end to thermal resistance that brings by the non eliminate contact from segment gap of the string type finned tube. 1 Features: The winding technology improves production efficiency and heat transfer, makes the average fin pitch and higher proportion between fins and tube. At the same time, the base tube can be protected from air erosion. 2 Application: LL-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system. The fin is wrapped around the tube with an overlapping foot and secured at each end. Gives good surface protection to the tube. Used for moderate temperature coolingapplications. Material: Copper, Carbon Steel, Copper Stainless Steel, Alloy, Aluminium Bare tube OD: 15.88-45mm Fin Pitch: 2.1-5.0mm Fin Height: <16mm

Email Details -

Overlapped LL TYPE Cooling Aluminum Fin Tube SA213 TP316

LL-type finned tube makes the trapezoidal cross-section forming by rolling combine closely with the heat flux density distribution size. The fins combine tightly with the tube,which makes the thermal efficiency higher and put an end to thermal resistance that brings by the non eliminate contact from segment gap of the string type finned tube. 1 Features: The winding technology improves production efficiency and heat transfer, makes the average fin pitch and higher proportion between fins and tube. At the same time, the base tube can be protected from air erosion. 2 Application: LL-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system. The fin is wrapped around the tube with an overlapping foot and secured at each end. Gives good surface protection to the tube. Used for moderate temperature coolingapplications. Material: Copper, Carbon Steel, Copper Stainless Steel, Alloy, Aluminium Bare tube OD: 15.88-45mm Fin Pitch: 2.1-5.0mm Fin Height: <16mm

Email Details