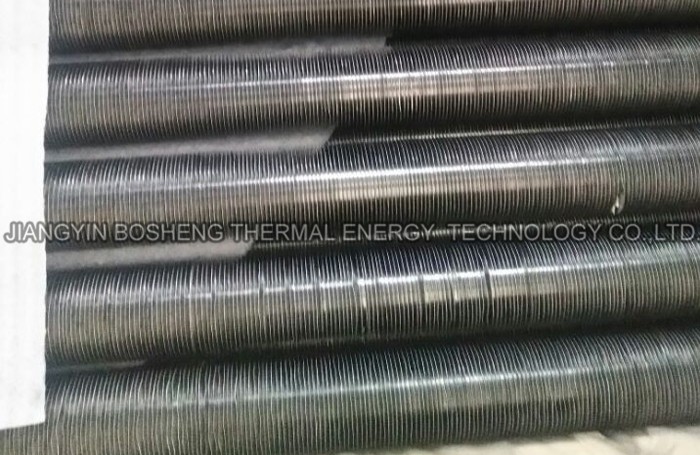

Overlapped Type LL Cooling Aluminum Fin Tube SA179

- BOSHENG

- JIANGYIN

- 2019

- 1000 M/DAY

LL-type finned tube makes the trapezoidal cross-section forming by rolling combine closely with the heat flux density distribution size. The fins combine tightly with the tube,which makes the thermal efficiency higher and put an end to thermal resistance that brings by the non eliminate contact from segment gap of the string type finned tube.

1 Features:

The winding technology improves production efficiency and heat transfer, makes the average fin pitch and higher proportion between fins and tube. At the same time, the base tube can be protected from air erosion.

2 Application:

LL-type finned tube mainly used in petrochemical, electric power, paper making, tobacco, building heating and other industry such as air cooler, air heater and air heater of food industry, plant starch spray drying system.

The fin is wrapped around the tube with an overlapping foot and secured at each end.

Gives good surface protection to the tube. Used for moderate temperature coolingapplications.

Material: Copper, Carbon Steel, Copper Stainless Steel, Alloy, Aluminium

Bare tube OD: 15.88-45mm Fin Pitch: 2.1-5.0mm Fin Height: <16mm

Material.

(1)Tubes shall comply with the requırements described in ASME SA179

(2)TUBE DIAMATER : 1.0” (25.4 mm)

(3)TUBE THICKNESS : 2,11mm (14 BWG)

(4)FIN MATERIAL : Aluminium 394 FINS/METERS,

(5)FIN OD : 571.5 MM,

(6)FIN THICKNESS : 0,4 MM,

(7)TOTAL FIN LENGHT : 9756 MM

6.PACKING AND SHIPPING

All materials to be packed suitably for overseas shipment .

6.1.All tube ends shall be covered with cap or provided with other closurer.

6.2.Interior of packıng shall be lined with waterproof tar paper or equivalent material.

6.3.In case boards are used in loading of packing boxes and crates they shall be made of good

Quality pine wood or similiar.material having a minimum of knots,resinow pine wood shall not be

used.Dimensions of the boards shall be suıtable for the weight of goods to be enclosed.

6.4.Crates shall be adequately blocked and fastened to prevent movement of the of the goods relative to the box

while in transit or durıng loadıng and unloading.

6.5.Shipping containers shall be adequately reinforged with banding wires and/or steel straps of Proper size and

strength to prevent deformation and damage.

6.6.A waterproof envolope containing fully detailed packıng list prepared and showing purchase order and date

must be securely fastened to the inside of cases and or wired on the bundles or loose places