fin tube

-

Hot

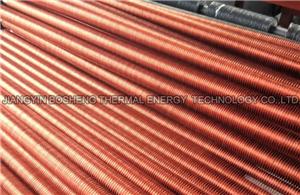

HF Sprial Serrated Fin Tube SA192 SA210 SA106Gr B Carton Steel Tubes With Cs Fin

ERW HF spiral fin tube The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using high frequency resistance welding technique. The High Frequency Resistance Welded Helical Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

HF SERRATED FIN TUBE for boiler ERW HF spiral fin tube fired heaters tubes High Frequency Resistance Welded Fin TubeEmail Details -

Hot

SA249-304 Low Fin Tube

Low fin tube Low fin tube are mainly used in the condnsers and evaporators for air cooler and refrigerator, absorption refrigerator, oil cooler and other heat exchangers. And other industry such as coal power stations, nuclear power stations,boat heat exchangers, air cooler. Heat recovery system, dryers and heaters in chemical industries.

Email Details -

Hot

SA334.GR.6 SMLS Tubes With Aluminium Fin

G Fin Tube (or Embedded Fin) Finis embedded into the outer wall of the tube, but gives no surface protection. Ingeneral use for continuous process applications; ie refineries, petrochemical,fertilizer and gas plants.

Email Details -

Hot

Extrude Fin Tube For Air Cooling SA210 Tube With Al1060F Fin

Extruded Fins / Extruded serrated Fins Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc. The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process.

Email Details -

Hot

SA179 Heat Exchanger Fin Tube With Spacer Boxes, AL1060 fin

Extruded Fins Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc. The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. Material: Aluminum, Copper, Carbon Steel, Alloy.etc. ASTM A106/A53,ASME SA210,ASTM A213,ASTM A179/A192

Email Details -

B111 C12200 Embedded Copper Fin Tubes With C12200 Fin

G Fin Tube (or Embedded Fin) Finis embedded into the outer wall of the tube, but gives no surface protection. Ingeneral use for continuous process applications; ie refineries, petrochemical,fertilizer and gas plants.

Email Details -

Hot

A213 TP304 Stainless Steel With AL1060 Fin For Air Cooler

G Fin Tube (or Embedded Fin) Finis embedded into the outer wall of the tube, but gives no surface protection. Ingeneral use for continuous process applications; ie refineries, petrochemical,fertilizer and gas plants.

Email Details -

Hot

G Type Copper Fin Tubes A179 Base Tube With C12200 Fin

G Fin Tube (or Embedded Fin) Finis embedded into the outer wall of the tube, but gives no surface protection. Ingeneral use for continuous process applications; ie refineries, petrochemical,fertilizer and gas plants.

Email Details -

Hot

Stainless Laser Fin Tubes Core Tube 304 With 304 Fin For Economizers

Laser welded fin tube 100% welding between fin and base tube without using any filler material, The laser welding process is carried out under the protective atmosphere, and no impurity of the weld seam. The Laser Welded Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

Email Details