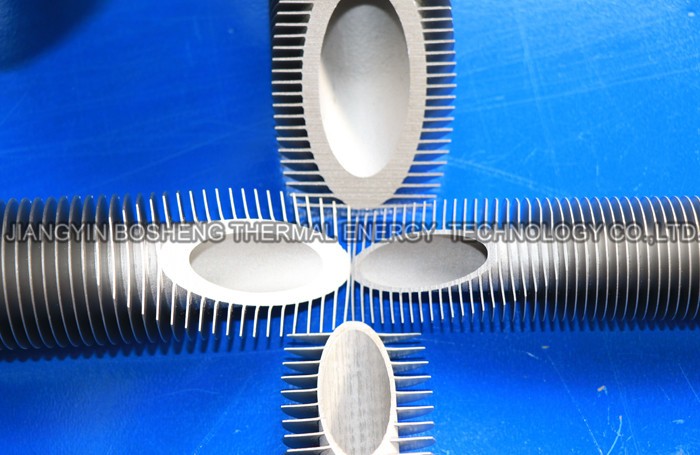

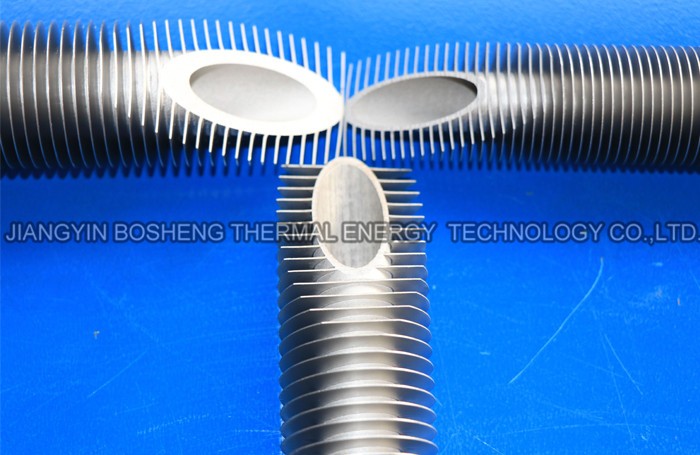

ASTM A789 GR.2205 Laser Welded Fin Tube With 316 Fin

- BOSHENG

- JIANGYIN, JIANGSU

- 2020

- 500 M/Day

Laser welding fin tube: Welding-forming surface-extended thermal-transfer tubes

The fin strip is welded continuously and spirally wound onto bare tube. And the tube and fins are bonded together by using lase welding technique. 100% welding between fin and base tube without using any filler material,

The laser welding process is carried out under the protective atmosphere, and no impurity of the weld seam

The Laser Welded Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc…

Type of finning : Laser Welded Fin tubes

Plain Tube : Material : ASTM A789 GR.2205

25.4mmODx2.0mm min THKx1170mmL

Fin: SS316L x OD47.4mm x 11H x1.0mm THK x230FPM

Packing method: SEA WORTHY PLYWOOD CASE WITH STEEL FRAME

PACKING AND SHIPPING

All materials to be packed suitably for overseas shipment .

All tube ends shall be covered with cap or provided with other closurer.

Interior of packıng shall be lined with waterproof tar paper or equivalent material.

In case boards are used in loading of packing boxes and crates they shall be made of good

Quality pine wood or similiar.material having a minimum of knots,resinow pine wood shall not be

used.Dimensions of the boards shall be suıtable for the weight of goods to be enclosed.

Crates shall be adequately blocked and fastened to prevent movement of the of the goods relative to the box

while in transit or durıng loadıng and unloading.

Shipping containers shall be adequately reinforged with banding wires and/or steel straps of Proper size and

strength to prevent deformation and damage.

A waterproof envolope containing fully detailed packıng list prepared and showing purchase order and date

must be securely fastened to the inside of cases and or wired on the bundles or loose places