Extruded Fin Tubes

-

Hot

Extrude Fin Tube For Air Cooling SA210 Tube With Al1060F Fin

Extruded Fins / Extruded serrated Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. -

Hot

SA179 Heat Exchanger Fin Tube With Spacer Boxes, AL1060 fin

Extruded Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process.

Material: Aluminum, Copper, Carbon Steel, Alloy.etc. ASTM A106/A53,ASME SA210,ASTM A213,ASTM A179/A192 -

Hot

SA334 Gr.6 Extruded & Serrated Heat Exchanger Fin Tube With Zinc Collar

Extruded Fins / Extruded serrated Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. -

Hot

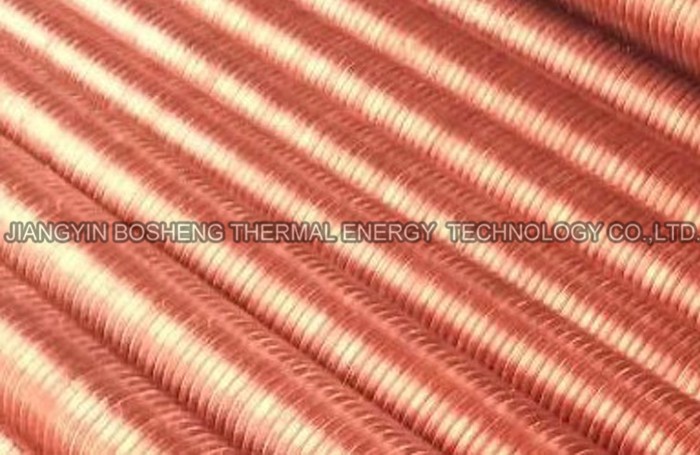

B111 C12200 Copper Extruded Fin Tubes With Al1060 Fin

Extruded Fins / Extruded serrated Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. -

SS304 Extruded Fin Tubes With C12200 Fin copper fin for air cooling

Extruded Fins / Extruded serrated Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. -

Hot

SA 213 TP316 Stainless Steel With Aluminium Fin

Extruded serrated type: with cold rolled extruded fin with longitudinal notches and inclined fin tips.

Email Details

Thirteen extrusion fining lines, daily capacity around 9000 meters

The extruded fin gives complete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process. -

Hot

SA 213 TP304 Stainless Steel With Aluminium Fin, AL1060 FIN

Extruded Fins / Extruded serrated Fins

Email Details

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition,etc.

The fin givescomplete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process.

The inspector should carry out visual inspecton of the finished finned tubes at 10% random rate,the tubes should be clean with no residue left from the finning process and no swarf between them.

The dimension inspection for finished finned tubes should be conducted in accordance with fin tube drawing.

At 10% random rate, the inspection contents are overall length, finned length, bare end length, middle bare tube length, fin tube out diameter, fin heigh, fin thickness , fin pitch, all measureed values for dimension should beaccording to the drawing. -

Extruded Serrated Fin Tube For Air Cooler SA179 With AL1060 Fin

Extruded type: with cold rolled extruded fin

Email Details

Thirteen extrusion fining lines, daily capacity around 9000 meters

The extruded fin gives complete protection to the base tube and is much stronger than the applied type due to work hardening of the fin material during the extrusion process.